In many industries, introduction of a linear movement at some stage in an operation series is frequently required. A pneumatic cylinder, which is likewise known as an air cylinder, is one of the simplest, maximum cost-effective solutions. Pneumatic cylinders are mechanical gadgets that convert the energy of compressed air to a linear movement.

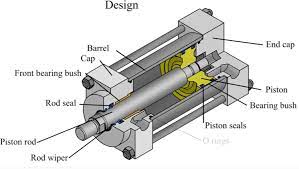

As proven in Figure 1, the cylinder barrel is sealed on each ends with a head cap and an end cap. Inside this cylinder, a piston drives the rod in a linear manner. When compressed air enters through the cap-end port, the piston movements far from the end cap and pushes the rod out. This motion is referred to as the positive/plus motion and the chamber related to this motion is referred to as the plus chamber. The minus chamber is positioned on the alternative aspect. When compressed air enters the rod-stop port the rod is driven lower back to the poor function.

The cylinder diameter is the internal diameter of the cylinder or the diameter of the piston. The stroke period identifies how a long way the piston/piston rod can travel. The diameter and stroke of a pneumatic cylinder are vital attributes with the aid of using which it’s far identified.

Function

Pneumatic cylinders may be both single-acting or double-acting.

Single Performing Cylinder

In a single-performing cylinder (SAC), air is driven to at least one aspect of the piston and is liable for the motion of the piston in handiest one path. The motion of the piston withinside the contrary path is accomplished with the aid of using a mechanical spring. A single-performing cylinder may be designed to be with base function negative (spring return) or base function positive (spring extend) relying on whether or not the compressed air plays the out stroke or the in-stroke respectively. In case of strain or energy loss, a single-performing cylinder has the benefit of returning the piston to a base function.

A disadvantage of single-performing cylinders is the inconsistent output pressure through a complete stroke because of the opposing spring pressure. Furthermore, the stroke of a single-performing cylinder may be restrained because of the distance the compressed spring takes up and spring period availabilities. The creation period of a single-performing cylinder is consequently longer than its real stroke.

Double Acting Cylinder

In a double-acting cylinder (DAC), air is driven to chambers on each aspects of the piston. Higher air strain on one aspect can power the piston to the alternative aspect. Double-performing cylinders are generally used , as they provide the person complete authority.

The benefits of double-performing cylinders are their longer strokes (as much as numerous meters) and steady output pressure through a complete stroke. These cylinders offer exceptionally higher manage and perform at better cycling rates. The drawbacks of double-performing cylinders are their want for compressed air for motion in each instructions and a loss of a described function in case of a energy or strain failure.

Detection of Cylindrical Position

To discover the placement of the piston, the piston may be prepared with a magnet. Body mounted sensors can then get hold of statistics from the magnetic field created and consequently apprehend the placement of the piston inside the cylinder. Reed switches and hall effect sensors are usually used sensor types.

Cushioning

The motion of the piston in a pneumatic cylinder may be very speedy because the compressed air enters the cylinder. This can create a hard shock while the piston hits the top or end cap. This imposes pressure on cylinder components, makes a noise, and transmits vibration to the gadget structure. To avoid this, the piston may be decelerated on the region of the caps through cushioning. Cushioning also can avoid the piston from rebounding (bouncing) off the end position. Most cylinders are prepared with end -of-stroke cushioning in one of the following ways:

Flexible surprise absorbers

In smaller cylinders wherein the effect isn’t always that high, flexible material is used on the cap end/head. This material is normally crafted from elastomers and in the shape of a ring. These bumpers are both incorporated as part of the piston or at the top and stop caps. This sort of cushioning is most appropriate for gradual running speeds, low loads and shorter strokes.

Adjustable pneumatic cushioning

In large cylinders with better piston speeds or more potent forces, the shock absorption may be performed through trapping a definite volume of air in the end position. At the end of the stroke the air can be compressed to generate a breaking impact. For this purpose, throttling non-return valves are set up without delay at the end ports of the cylinder. This permits the free inflow of pressurized air at the same time as permitting the adjustment of the location of the exhaust port with an adjusting screw. This approach of cushioning is wear-free and gives foremost cushioning performance. Depending at the running stress and the cylinder force, the screw settings at the cylinder want to be adjusted for best cushioning. Too a whole lot cushioning consequences in gradual strokes and too little cushioning will increase the endof-stroke shock.

Self-adjusting pneumatic cushioning

In this approach, the exhaust air escapes via slots in a cushioning boss. The cross-sectionof this exhaust relies upon at the stroke. This will permit for the cushioning to mechanically regulate to special tiers of power through converting loads and speeds.

Standards

Pneumatic cylinders had been standardized to be interchangeable with merchandise of various manufacturers. Therefore, in a standard cylinder, the mounting dimensions, cylinder bore and stroke, piston rod traits and air ports rely upon the type/standard. However, there are nonetheless severa non-standard cylinders for unique applications.

Round ISO 6432 (eight-25 mm)

ISO 6432 (additionally referred to as mini cylinder or spherical cylinder) is a metric ISO standard relevant to single rod pneumatic cylinders with bores from eight mm to twenty-five mm and a maximum pressures of up to ten bars (one thousand ok Pa). This standard establishes a metric collection of mounting dimensions required for the interchangeability of the cylinders. This pneumatic cylinder standard does now no longer have manual damping adjustment. The ISO 6432 is a really perfect compact cylinder line appropriate for automations systems in analytics, diagnostic instrumentation, bottling, car and industrial kitchen and laundry equipment. View the standard here.

Profile ISO 15552 (32-320 mm)

ISO 15552 (which has changed ISO 6431 and VDMA 24562) establishes metric mounting dimensions, bore sizes, mounting styles, piston rod traits and strokes for single or double rod pneumatic cylinders with a maximum working pressure of up to ten bar (one thousand ok Pa) and bore sizes from 32 mm to 320 mm. This standard applies to cylinders with removable mountings. VDMA 24562 is common in Germany and is for profile and tie-rod cylinders. The ISO 15552 pneumatic cylinder collection have adjustable damping, or cushioning, that facilitates to obtain best damping. So, it’s far appropriate for efficient motion of massive loads. It is commonly utilized in wellknown automation structures in machine and systems constructions, food and beverage industry, etc. View the same old here.

Compact ISO 21287 (20-a hundred mm)

ISO 21287 applies to single rod compact pneumatic cylinders with a maximum working pressure of up to ten bar (one thousand ok Pa) and bore sizes from 20 mm to a hundred mm. This pneumatic cylinder collection isn’t always equipped with adjustable cushioning. However, there are rubber bumpers at each ends for cushioning. The ISO 21287 pneumatic cylinder collection are compact and mild weight, accordingly appropriate for applications which have space limitations. View the same old here.

Choosing Pneumatic Cylinder

We have been supplying pneumatic cylinders for more than 15+ years and so we are able to provide the suitable technical data to ease your process.